Bounce Back Bollards

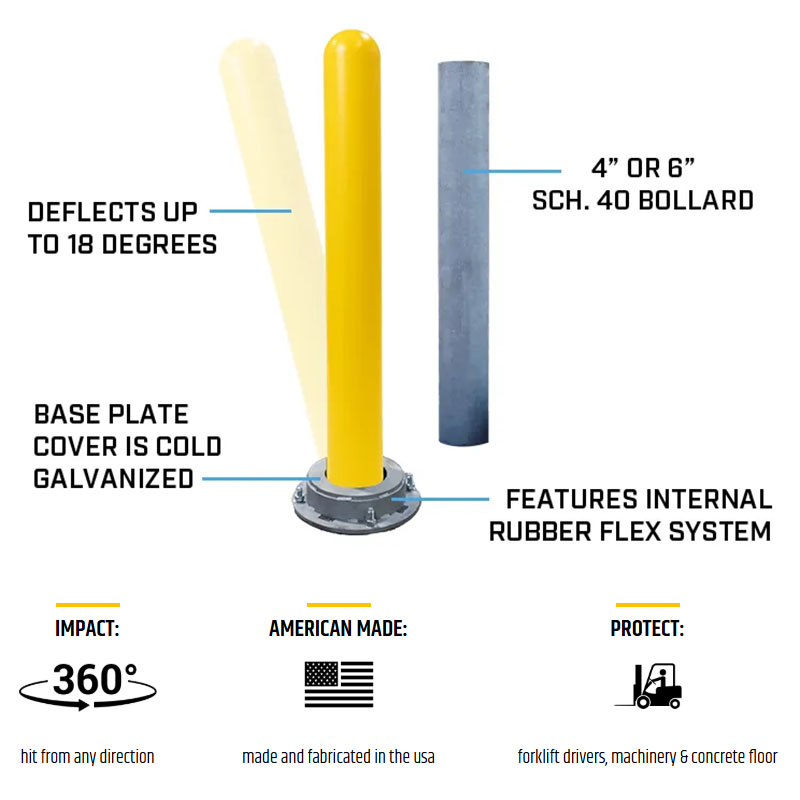

- Impact Absorption: Deflects up to 18 degrees and returns upright, minimizing damage.

- Durable Construction: Made with 4″ or 6″ Schedule 40 steel and a rubber flex system.

- High Resistance: 6″ bollard can stop a 10,000 lb. forklift at 5 mph.

- Floor Protection: Reduces stress on concrete and anchors, preventing costly repairs.

- Quick Installation: Easy to set up and ideal for warehouses, plants, and high-traffic areas.

Bounce Back Bollards: Durable, Flexible, and Impact-Resistant

Give A Little, Save A Lot

Our Bounce Back Bollards are innovative steel bollards designed to absorb impact, minimize damage, and return to their upright position. Featuring a rubber flex system and spring back bollards technology, these surface-mounted rebound bollards are ideal for high-traffic areas in warehouses, plants, and facilities.

Key Features and Benefits

- Impact Absorption: Deflects up to 18 degrees upon impact, protecting vehicles, flooring, and the bollard itself.

- Durable Construction: Built with 4" or 6" Schedule 40 steel pipe and a rubber flex system for maximum resilience.

- High Impact Resistance: The 6" bollard can stop a 10,000 lb forklift traveling at 5 mph, giving operators a chance to react and avoid further damage.

- Protects Floors and Anchors: The flex system reduces stress on concrete and base plate anchors, preventing costly repairs.

- Quick Installation: Fast and simple to install, saving maintenance teams time and effort.

Applications

Bounce Back Bollards are perfect for:

- Forklift Areas: Protect machinery and structures in high-traffic zones.

- Machine Guarding: Safeguard equipment in industrial facilities.

- Warehouse Safety: Minimize damage in busy work environments.

- Vehicle Impact Zones: Provide a flexible, reliable barrier for vehicle guidance.

Product Details

Materials:

- Base Plate: 1/2" U.S. steel with a cold-galvanized cover

- Rubber Flex System: Includes Flex Base and Flex Topper

- Bollard Pipe: 4" or 6" Schedule 40 steel, 48" height

- Bollard Cover: Standard 1/4" cover included, with other options available

Impact Capability:

- Withstands hits from any direction, providing 360-degree protection

American-Made:

- Proudly fabricated in the USA with premium materials

Why Choose Bounce Back Bollards?

- Innovative Design: Combines the strength of steel bollards with the flexibility of spring back bollards to reduce damage.

- Cost-Effective Solution: Saves on repairs for machinery, floors, and bollard replacements.

- Reliable Performance: Absorbs impact and resets to upright form for ongoing protection.

- Versatile Applications: Ideal for various industrial and commercial environments.

Contact Us Today

Discover how our Bounce Back Bollards can enhance safety and efficiency in your facility. Contact our team now to learn more about this innovative bollard solution or to request a quote!

Call (800) 448-2647 to speak with a product specialist about our steel bollards, today!

Highway Signals is a division of the Tamis Corporation. Tamis is located just outside Pittsburgh, Pennsylvania.

Additional information

| Material | Steel |

|---|

Product FAQs

FAQs About Bounce Back Bollards

1. What are Bounce Back Bollards used for?

Bounce Back Bollards are designed to provide flexible, impact-absorbing protection in high-traffic areas, such as warehouses, industrial facilities, and forklift zones. They safeguard machinery, vehicles, and flooring by deflecting and returning upright after impact.

2. How do Bounce Back Bollards work?

These bollards feature a rubber flex system that allows them to absorb energy and deflect up to 18 degrees upon impact. Once the impact is over, the bollard returns to its upright position without sustaining significant damage.

3. What materials are used in Bounce Back Bollards?

Bounce Back Bollards are constructed with:

- 4″ or 6″ Schedule 40 steel pipe

- A 1/2″ U.S. steel base plate with a cold-galvanized cover

- A rubber flex system for flexibility and durability

4. Can Bounce Back Bollards handle heavy impacts?

Yes, the 6″ bollard is capable of stopping a 10,000 lb forklift traveling at 5 mph, providing excellent protection for high-impact zones.

5. What sizes are available?

Bounce Back Bollards are available in 4″ or 6″ Schedule 40 steel pipes, standing 48″ tall.

6. Are bollard covers included?

Yes, each bollard comes with a 1/4″ Bollard Cover as standard. Additional cover options are available to suit specific branding or color requirements.

7. How do Bounce Back Bollards protect flooring and anchors?

The rubber flex system minimizes stress on the concrete and base plate anchors during impacts, preventing costly floor repairs and anchor damage.

8. Are Bounce Back Bollards easy to install?

Yes, these bollards feature a surface-mounted design with a base plate for quick and easy installation.

9. Are these bollards suitable for outdoor use?

While Bounce Back Bollards are primarily used indoors, the cold-galvanized base plate provides some resistance to rust, making them suitable for covered outdoor areas or transitional spaces.

10. Can they be customized?

Yes, bollard covers can be customized with various colors and branding options to fit your facility’s needs.

11. Are Bounce Back Bollards made in the USA?

Yes, all Bounce Back Bollards are proudly fabricated in the USA using premium materials.

12. What vehicles or equipment can these bollards protect against?

These bollards are specifically designed to handle impacts from forklifts, carts, and other equipment commonly used in industrial and commercial environments.

Feel free to adapt these FAQs further based on customer feedback or specific inquiries!